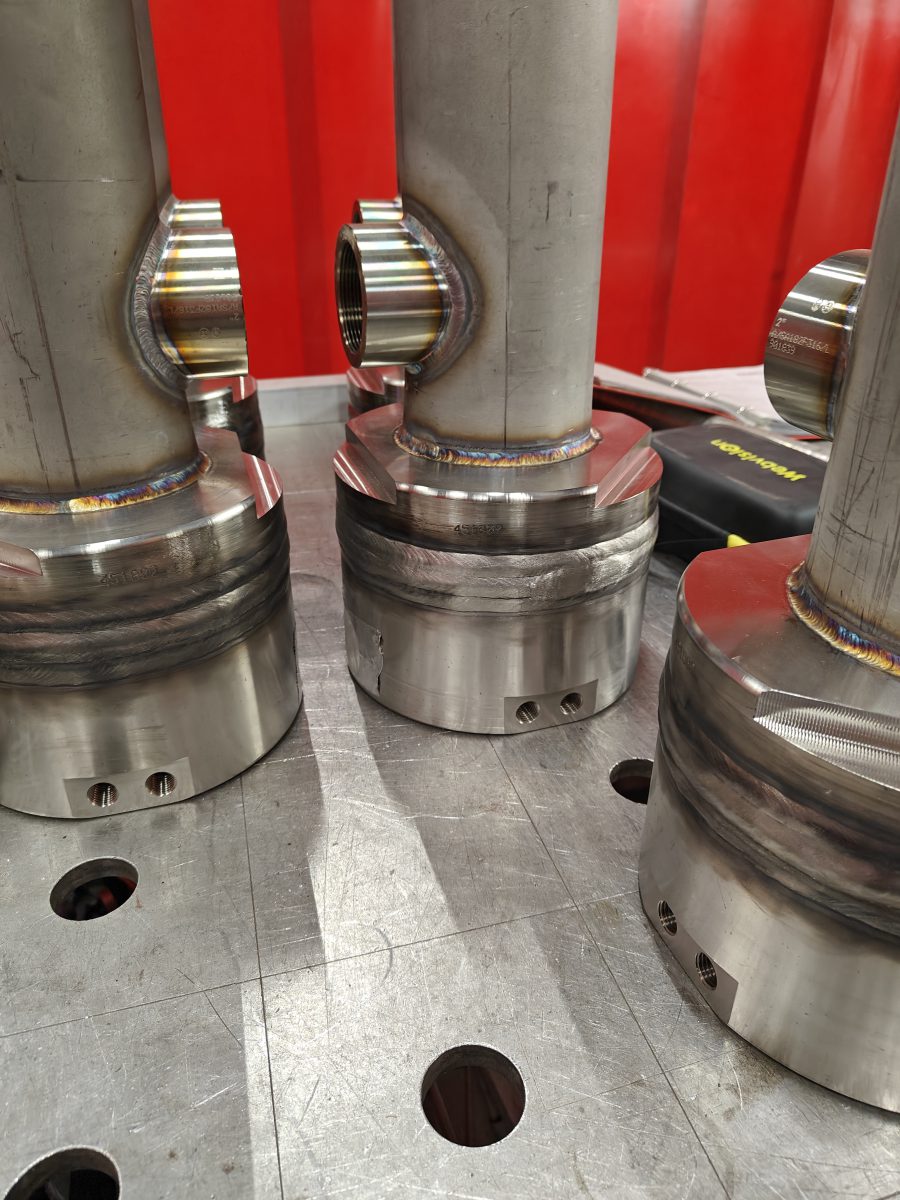

This project includes a set of 3 coolers for a hydrogen fuel station. 1 cooler is for unloading the high pressure hydrogen fuel truck to the fuel station. 2 coolers are for the cooling of the hydrogen from the dispensor to the user’s fuel tank. Filling of the tank is done at 380 barg, the design pressure of the coolers is 550 barg.

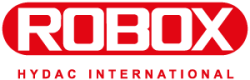

For high-pressure hydrogen applications, ROBOX has developed heat exchangers in-house, our so-called micro Shell&Tubes (mS&T). These are similar to a TEMA type BEU and BFU, where hydrogen passes through the tubes and the bonnet is completely welded. In addition, the mS&T uses 1/4″ tubes to minimize required wall thickness and maximize surface area. This results in a compact heat exchanger.

In this case, the coolers need to be placed in the dispenser of the fuel station, replacing a plate-type heat exchanger. Because the space was very limited, we made 2 short shells in series to meet the cooling capacity. This way, the customer does not need to make any further adjustments to the layout of the dispenser.

MicroShell & Tube heat exchangers. 2 shells in series, 1-pass shell and 2 pass tube side. U-bundle that is integrally welded with cover and body. TEMA type BEU. Stainless steel 316(L), PED cat.IV/Mod.H1 and ASME BPVC VIII.